Fusion Edge Laser Series

Laser engraving, cutting, and marking solutions for your business.

Fusion Edge Laser Machines

Business Series – 12, 24, & 36

Featuring up to 120 IPS (3.05 m/s) engraving speeds, 5g acceleration, and a variety of wattage configurations, the Fusion Edge Laser Series from Epilog can help you boost your productivity and expand your product offerings.

Comprised of the Fusion Edge 12, 24, and 36, all the machines in the Edge Series feature Epilog’s revolutionary IRIS™ Camera System that gives laser operators a real-time image of the engraving table so they can quickly and accurately position their artwork on even the most uniquely shaped items.

Systems in the Fusion Edge Series can engrave and cut a variety of materials including wood, acrylic, fabric, cork, rubber, slate, glass, and so much more. Additionally, these easy-to-use laser machines include a 7-inch LED-lit touch display, trace capabilities at the laser, as well as SAFEGUARD™ features that keep the mechanics of your laser cleaner than ever.

CLOSER LOOK:

Request Free Samples and Information

"*" indicates required fields

This site is protected by reCAPTCHA and the Google Privacy Policy and Terms of Service apply.

| Laser Machine: | Fusion Edge 12 | Fusion Edge 24 | Fusion Edge 36 |

|---|---|---|---|

| Work Area: |

24″ x 12″ x 7″ (610 x 305 x 178 mm) |

24″ x 24″ x 10″ (610 x 610 x 254 mm) |

36″ x 24″ x 10″ (914 x 610 x 254 mm) |

| Laser Options: | CO2 or Fiber | CO2 | CO2 |

| CO2: | 50 or 60 watts | 50 or 60 watts | 60, 80, or 100 watts |

| Fiber: | 30 watts | n/a | n/a |

| IRIS™ Cameras: | 1 overhead | 2 overhead | 2 overhead |

| More Tech Specs | |||

FEATURES: Machine Enhancements Designed to Increase Productivity

ACCESSORIES: Upgrade your laser system

-

Pin Table

Vector CuttingThe Pin Table incorporates movable pins that allow you to raise and support the cutting material in locations where the laser will not be cutting, which helps eliminate backside reflection. The table also allows you to place pins to support parts that would normally fall out of the cutting pattern, and the handy removable surface plate makes it easy to clean up small parts easy without removing the Pin Table. -

Air Assist Pump

CompressorThis high-quality air compressor blows a constant stream of air across the cutting area, which removes heat and combustible gases from the work area and provides the best cutting results available. The rubber vibration-dampening feet reduce the noise level of the compressor, and connection is a breeze with our quick-connect inlet and outlet ports on the compressor and the laser system. -

3-Jaw Chuck

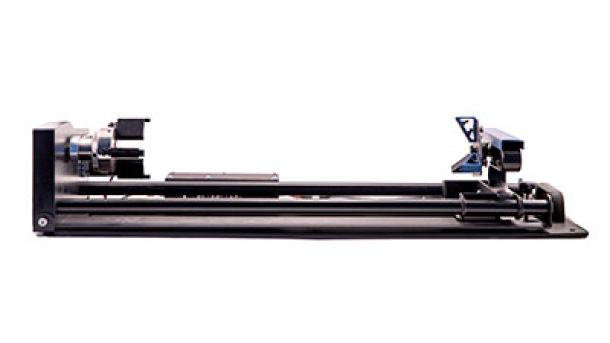

Rotary AttachmentWith the 3-Jaw Chuck rotary, objects are clamped into the device’s 3-jaw chuck, allowing you to rotate cylindrical or oddly-shaped items in applications that demand more precise alignment. -

Rim-Style

Rotary AttachmentThe Rim-Style rotary attachment adds the ability to engrave bottles, glasses, flashlights, or any other cylindrical item. The rotary attachment is as easy to set up as placing your product on the rotary, raising or lowering the scissor lift to level the engraving area, and printing to the laser. -

Floor Stand

Fusion Edge 12An easy-to-use stand for moving your laser around your workspace, this wheeled cart is specially designed for the Fusion Maker and Edge 12 laser machine. It provides you greater versatility within your work environment and the ability to easily transport your machine to different locations.

Note: The Fusion Edge 24 and 36 are standalone machines with a built-in pedestals.

-

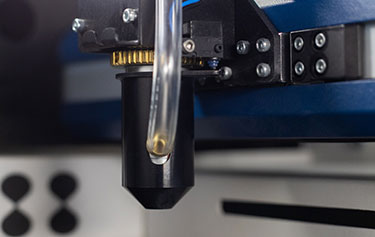

1.5″ Optional Lens

Highest-Resolution EngravingAlthough the standard 2.0-inch lens provides amazing detail, our 1.5-inch optional lens assembly is designed for the highest-resolution engraving and etching of extremely small fonts. -

4.0″ Optional Lens

Cutting Thicker MaterialsThe 4″ optional lens produces a focused beam over a longer vertical distance, which makes it ideal for cutting through very thick materials. -

PhotoLaser Plus Advanced

Design SoftwarePhotoLaser Plus takes photo engraving with your Epilog laser to the next level by easily processing photos for engraving on all types of materials. Epilog Laser has partnered with CADLink to bring you the industry’s best photo processing software: PhotoLaser Plus. The easy-to-use software interface and powerful photo processing tools allow you to create the highest-quality photo engravings in the industry.

MATERIAL COMPATIBILITY: Quick guide for your Epilog Laser Machine

-

Layered Sign

Amazing Detail!

Acrylic Sign

Amazing Detail!

Numbered Sign

Amazing Detail!

Acrylic LED Sign

Amazing Detail!

Acrylic Employee Sign

Amazing Detail! -

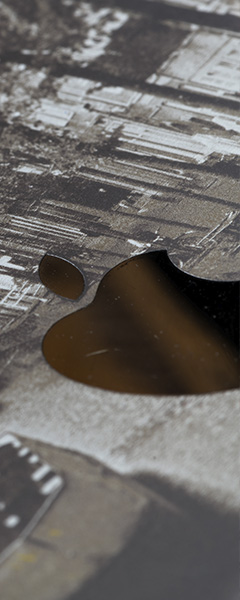

Engraving iPad

Amazing Detail!

Water Bottles

Amazing Detail! -

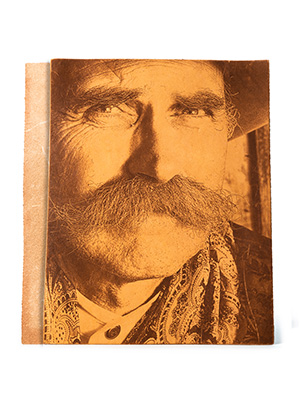

Photo on Leather

Amazing Detail!

Engraving on Hats

Amazing Detail!

Leather Journal

Amazing Detail!

Pet Accessories

Amazing Detail!

Leather Pillows

Amazing Detail! -

Wine Bottles

Amazing Detail!

Shot Glasses

Amazing Detail!

Pint Glasses

Amazing Detail! -

3D Cardboard Rhino

Amazing Detail!

Paper Monsters

Amazing Detail!

Layered Carboard Wave

Amazing Detail!

Laser Engraved Packaging

Amazing Detail!

Amazing Detail!

Amazing Detail! -

Wood

HouseAmazing Detail!

Wedding Photos

Amazing Detail!

Cutting Board

Amazing Detail!

Wine Phone Booth

Amazing Detail!

Ornate Detail

Amazing Detail!

Rolling Pins

Amazing Detail! -

Material Engrave Cut Acrylic Anodized Aluminum Ceramic Cloth Coated Metals Corian Cork Delrin Fabric Fiberglass Material Engrave Cut Glass Leather Marble Stainless Steel * Brass * Matte Board Melamine Mother of Pearl Mylar Painted Metals Material Engrave Cut Paper Plastic Pressboard Rubber Tile Wood Wood Veneer Titanium * Bare Metals * * CO2 lasers will mark bare metals when coated with a metal marking solution. For more information, visit our laser metal marking page.

Do you have a material you would like us to test? Our Applications Team would be happy to assist you.

TECHNICAL SPECIFICATIONS: Fusion Edge 12, 24, and 36 Laser Machines

Laser Machine: |

FUSION EDGE 12Business Series

|

FUSION EDGE 24Business Series

|

FUSION EDGE 36Business Series

|

Work Area: |

24″ x 12″ (610 x 305mm) | 24″ x 24″ (610 x 610mm) | 36″ x 24″ (914 x 610mm) |

Material Thickness: |

7″ (178 mm) | 10″ (254 mm) | 10″ (254 mm) |

Laser Tube Types: |

|

CO2: air-cooled, metal/ceramic Waveguide tube, 10.6 micrometers | CO2: air-cooled, metal Waveguide tube, 10.6 micrometers |

Laser Tube Wattages: |

|

CO2: 50 or 60 watts | CO2: 60, 80, or 100 watts |

IRIS™ Camera System: |

1 overhead | 2 overhead | 2 overhead |

Wireless Connectivity: |

Included | Included | Included |

Included Lenses: |

|

CO2: 2″ | CO2: 2″ |

Optional Lenses: |

CO2: 1.5″ or 4″ | CO2: 1.5″ or 4″ | CO2: 1.5″ or 4″ |

Resolution: |

Fully-flexible & user-controlled from 75 – 1200 dpi | Fully-flexible & user-controlled from 75 – 1200 dpi | Fully-flexible & user-controlled from 75 – 1200 dpi |

Maximum Engraving Speed (inches/meters per second): |

120 IPS (3.05 m/s) with 5G acceleration. Computer-controlled in .001 increments up to 100%. Color mapping feature links Speed, Power, Frequency, and Raster/Vector mode. | ||

Print Driver & Software: |

Laser Dashboard™, Epilog Job Manager™ | Laser Dashboard™, Epilog Job Manager™ | Laser Dashboard™, Epilog Job Manager™ |

Internal Memory: |

Store multiple files up to 1 GB. Engrave any file size. | Store multiple files up to 1 GB. Engrave any file size. | Store multiple files up to 1 GB. Engrave any file size. |

Operating Modes: |

Optimized Raster, Vector, and Combined mode. | Optimized Raster, Vector, and Combined mode. | Optimized Raster, Vector, and Combined mode. |

Super-Silent Cooling Fans: |

Included | Included | Included |

Motion System: |

Brushless DC Servo Motors | Brushless DC Servo Motors | Brushless DC Servo Motors |

X-Axis Bearings: |

Ground & polished stainless steel, Teflon-coated, self-lubricating bearings. Dual blocks on X-axis for greater rigidity | ||

Belts: |

Advanced B-style double-wide Kevlar precision drive belts. | Advanced B-style double-wide Kevlar precision drive belts. | Advanced B-style double-wide Kevlar precision drive belts. |

Job Trace: |

Included | Included | Included |

Auto Focus: |

Included | Included | Included |

Touch Screen: |

Included | Included | Included |

Included Table: |

|

Vector Cutting Table (Grid-Style) | Vector Cutting Table (Grid-Style) |

Air Assist Pump: |

Optional | Optional | Optional |

Max Table Weight: |

Static: 90 lbs (40.8 kg), Lifting: 60 lbs (27.2 kg) |

||

Size (W x D x H): |

39.5″ x 26.5″ x 17.9″ 1003 x 673 x 455 mm |

41.52″ x 32.81″ x 38.04″ 1055 x 834 x 967 mm |

53.52″ x 32.81″ x 38.04″ 1359 x 834 x 967 mm |

Weight: |

138 lbs (63 kg) | 225 lbs (102 kg) | 260 lbs (117 kg) |

Electrical: |

Voltage: Auto-switching 100-120, Amp draw-MAX: 13A Voltage: Auto-switching 220-240, Amp draw-MAX: 6.5A 50 or 60 Hz, single phase |

||

Ventilation: |

350-400 CFM (595-680 m3/hr) external exhaust to outside or internal filtration unit required. One output port, 4″ (102 mm) diameter |

||

Safeguard Features: |

Included | Included | Included |

Request More Information

Request More Information

and get more info from your local distributor.